In the world of advanced manufacturing, innovation is a constant driving force. Today, one of the most compelling advancements is the ebeam machine. This technology is transforming how materials are processed, with applications spanning from aerospace to medical devices. But what exactly is an ebeam machine, and why should you, as a manufacturing enthusiast or professional, care about it?

What is an Ebeam Machine?

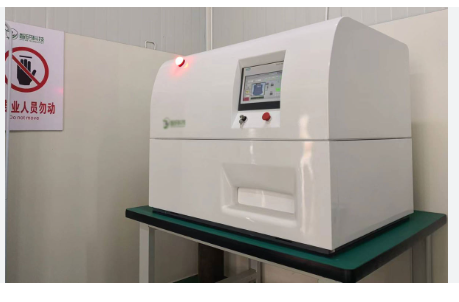

An ebeam machine, or electron beam machine, utilizes high-energy electrons to process materials. It’s a precise and versatile technology that can be used for welding, cutting, and surface treatment. Unlike traditional methods, ebeam processing operates in a vacuum, which eliminates contamination and oxidation.

This machine works by emitting a concentrated beam of electrons that generate heat when they strike a material’s surface. This heat can melt or evaporate materials, allowing for precise and controlled manufacturing processes. The result? High-quality products with minimal waste.

The precision offered by ebeam technology is unparalleled. It allows manufacturers to work with delicate materials and produce intricate designs that would be challenging with conventional methods. This capability is particularly valuable in industries where precision is paramount.

The Role of Ebeam Machines in Industry

Ebeam machines have found a vital role across various industries. In aerospace, they are used to create complex components with lightweight materials, enhancing fuel efficiency and performance. The automotive industry employs this technology for precision welding of critical components, ensuring durability and safety.

In the medical field, ebeam machines are instrumental in producing surgical instruments and implants. The ability to sterilize and shape materials without contamination is crucial in maintaining the highest standards of patient safety and effectiveness. This technology allows for the customization of medical devices to meet specific patient needs.

Furthermore, in the electronics sector, ebeam technology is used to manufacture microchips and circuit boards. The fine detail achievable with ebeam processing supports the miniaturization trend, leading to smaller, more powerful electronic devices.

Advantages of Using Ebeam Machines

The advantages of ebeam machines are numerous. Firstly, their precision reduces material waste, making the manufacturing process more sustainable. This not only saves costs but also lessens the environmental impact, aligning with the growing emphasis on green manufacturing practices.

Secondly, the speed of ebeam processing can significantly reduce production times. This efficiency translates to increased productivity and cost savings for manufacturers. The ability to quickly adapt to production changes makes these machines ideal for industries that require flexibility.

Finally, the quality of products produced with ebeam technology is consistently high. The controlled environment and precision of the process minimize defects, resulting in superior products. This reliability is essential in industries where product failure is not an option.

Challenges and Considerations

Despite its benefits, adopting ebeam technology requires careful consideration. The initial investment can be significant, and operators must be trained to manage and maintain the equipment properly.

Additionally, the vacuum environment necessitated by ebeam machines can limit the size of components that can be processed. Manufacturers must evaluate whether their products fit within the operational constraints.

Businesses should also assess the compatibility of their existing systems with ebeam technology. Integrating this advanced machinery into production lines may require modifications and a clear understanding of how it interacts with other processes.

Innovations in Ebeam Technology

The field of ebeam technology is continually evolving. Recent innovations focus on increasing the energy efficiency of these machines and expanding the range of materials they can process. Research is underway to develop portable ebeam machines, which could revolutionize field operations, especially in remote locations.

The advancement of AI integration is another exciting development. AI can enhance the precision of ebeam processing by adjusting parameters in real time, ensuring optimal outcomes. This synergy between AI and ebeam technology promises to further boost manufacturing capabilities.

Furthermore, partnerships between manufacturers and research institutions are leading to groundbreaking applications. These collaborations are exploring new alloys and composites that can be effectively processed using ebeam technology, broadening its potential uses.

Implementing Ebeam Machines in Your Business

For businesses considering ebeam technology, it’s essential to conduct a thorough cost-benefit analysis. Evaluate how the technology can enhance your product offerings and improve operational efficiency. Engage with experts to understand the best practices for implementation.

Consider pilot projects to test the technology’s capabilities within your specific production environment. This approach allows you to identify challenges and benefits unique to your operations before committing to full-scale integration.

Collaboration with technology providers can also streamline the adoption process. These partners can offer valuable insights and training, ensuring your team is well-equipped to leverage the full potential of ebeam machines.

Future Outlook for Ebeam Machines

The future of ebeam technology is bright. With continued innovation, the machines are expected to become more accessible and versatile. Their role in advancing manufacturing processes will likely expand, driven by the demand for high-quality, sustainable products.

Industry leaders are investing in research to push the boundaries of what ebeam machines can achieve. This commitment to exploration and development is set to unlock new possibilities in precision manufacturing.

The integration of digital technologies will further enhance the capabilities of ebeam machines. From improved data collection to predictive maintenance, these advancements will refine manufacturing processes and promote efficiency.

Conclusion

Ebeam machines represent a significant leap forward in manufacturing technology. Their precision, efficiency, and versatility offer numerous advantages across various industries. However, successful implementation requires careful planning and consideration.